Description

Keep one for microscope work, two for the fleet.

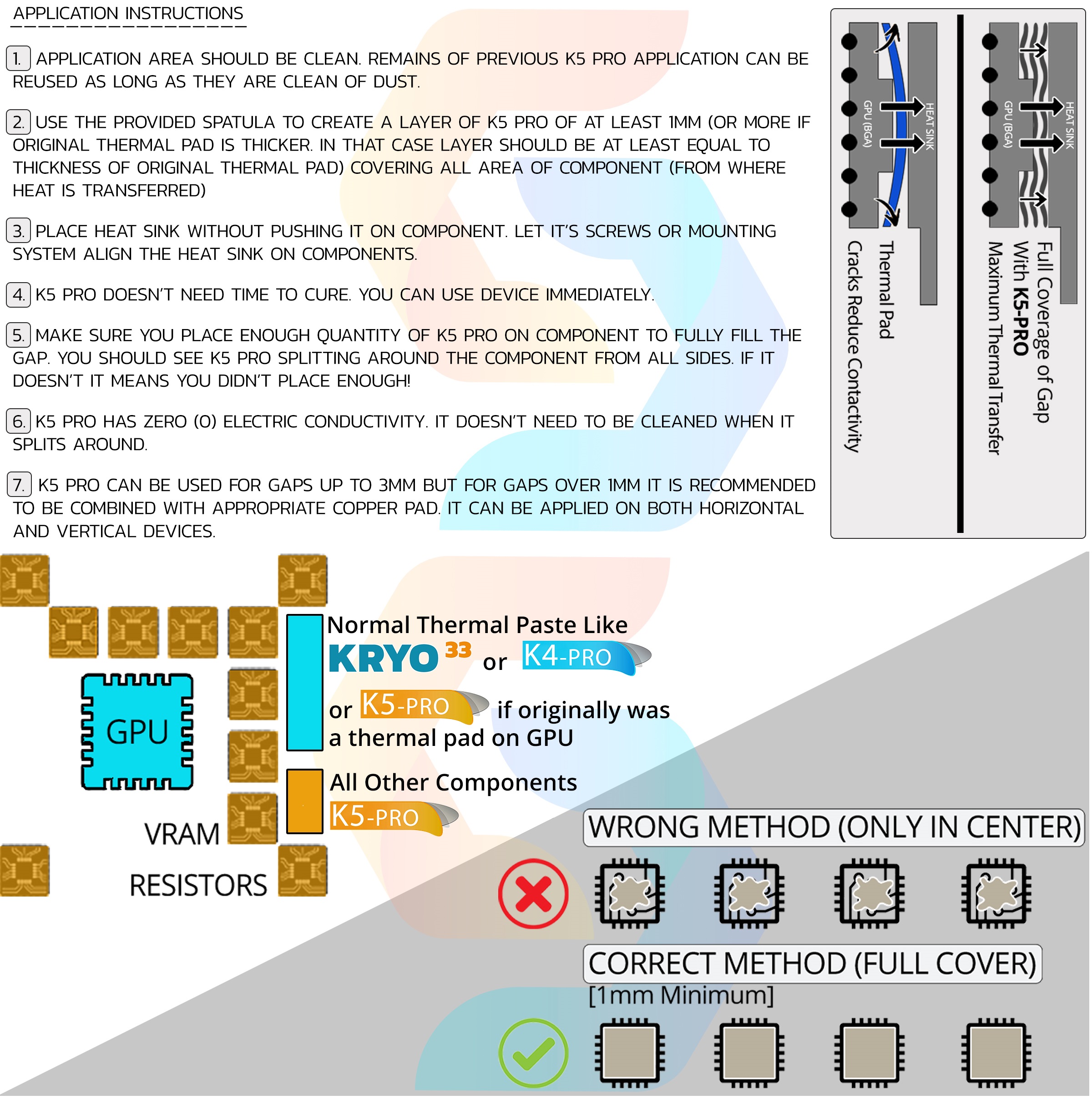

K5-PRO 3x20g equips your bench with three 20 g jars of our viscous, non conductive thermal putty—recognized worldwide since 2013 for accessible, repeatable pad replacement. It spreads smoothly, holds its shape, and maintains cohesive contact over uneven surfaces, restoring dependable heat transfer without stacking pads or guessing thickness.

With 60 g total split across three jars, this shop pack supports busy teams while preserving freshness. Keep one jar dedicated to microscope only work, one for general service, and one sealed as inventory. The split format minimizes exposure to dust, simplifies stock rotation, and ensures consistent texture from first application to last.

As a daily solution, K5-PRO covers the vast majority of pad replacement scenarios on laptops, desktops, and consoles. It spreads smoothly, holds its shape, and maintains cohesive contact between components and heat sinks—even across uneven surfaces and around height variations—so you can restore reliable heat transfer without hunting for exact pad thicknesses.

Beyond standard repairs, K5-PRO also solves thermal transfer challenges in custom or compact builds. Use it to create a controllable heat bridge from hot components to metal housings or frames in devices such as home routers, access points, LED light bars/panels, DVRs/NVRs, and single board computer enclosures. Users around the world have reported lower memory temperatures, quieter fans, and improved stability after replacing aged or poorly sized pads, with consistent gains when dealing with mixed gap heights and irregular interfaces. Store sealed, away from frost and dust; keep in a cool, dry place to maintain long term stability.

Packet includes:

• 3 × 20 g jars of K5-PRO thermal putty

• 1 × wooden applicator

• 1 × instruction leaflet

Born from the eternal battle between heat and control, K5-PRO carries the spirit of the engineer who mastered the fire.

A legend of balance between power and precision, forged for those who protect performance.

*Computer Systems Materials Science Laboratory testing (comparative technique; P. Karydopoulos, P. Frantzis, N. Karagiannis; MSAIJ, 2014).

• Establishes a stable, shapeable interface that equalizes irregular gaps for proper heat sink seating and consistent thermal transfer across VRAM/VRM and frame edge contact points.

• Packaging advantage – 3 × 20 g jars: 60 g total for frequent service while keeping each jar fresh; assign jars to benches or technicians, and rotate stock easily.

• Bridges gaps up to 3 mm (≈1 mm optimal) without sag; particularly effective where mixed component heights and standoffs make pad selection difficult.

• >5.3 W/m·K* thermal conductivity and a −90 °C to 250 °C operating window; electrically non conductive and easy to rework during future service.

• Supports DIY and workshop projects, including heat bridging to metal housings in routers, LED assemblies, DVRs/NVRs, and compact embedded systems with limited airflow.

• K5-PRO is compatible with Apple iMac, Acer Nitro, ASUS ROG, MSI laptops, PlayStation 4, Nintendo Switch, Xbox One, and NVIDIA GeForce GTX 10series boards.

Success stories using K5 PRO:

K5 PRO videos from our work shop. [How to apply and various testing]

Q: What is the difference between thermal paste, thermal putty (sometimes called a “liquid thermal pad”), and a thermal pad?

A: Thermal paste is a thin compound used on flat, tightly clamped interfaces such as a CPU/GPU die to a heatsink. Thermal putty is a soft, formable material designed to bridge larger, uneven gaps where a normal paste cannot maintain contact—for example around VRAM or power stages. A thermal pad is a pre cut sheet used by manufacturers to fill gaps quickly during assembly. In many repairs, thermal putty can replace pads to restore contact with better conformity and easier fit when heights vary.

Q: When should I choose a thermal putty instead of a pad or paste?

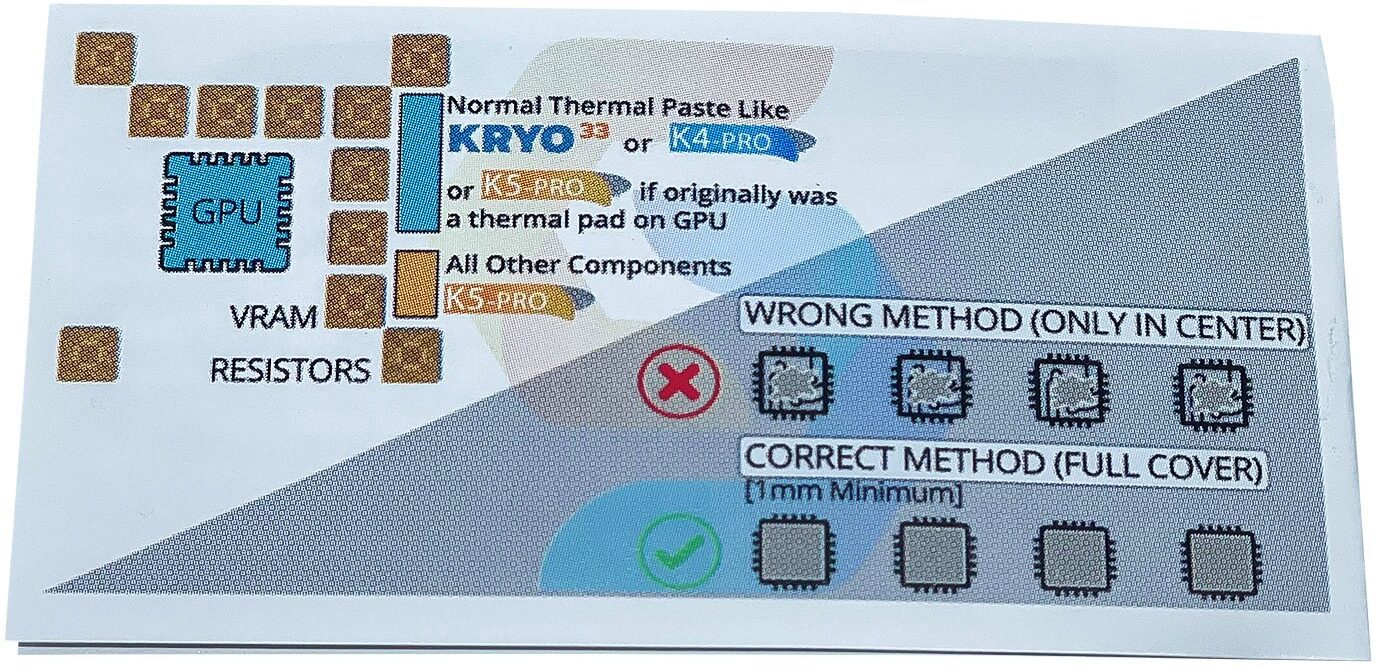

A: Choose a putty when the interface has mixed heights or gaps above roughly 0.5 mm. K5 PRO® (~0.5–3 mm, ≈1 mm optimal), UPSIREN U6 PRO® (~1–2 mm), K5 PRO® Mt. Olympos Edition (1–4 mm), and UPSIREN UX PRO Ultra (2–4 mm) are purpose built for these conditions. For flat, high pressure die interfaces (CPU/GPU), a paste such as KRYO33 or K4 PRO is appropriate; a phase change pad such as PTM7950 by CSGR® works where the heatsink exerts uniform pressure and you want clean, repeatable assembly.

Q: How do I estimate the correct thickness when replacing a pad with putty?

A: Disassemble and clean the area, then dry fit the heatsink without fully tightening. Measure the original pad if available. Start with a thin film and build until the total layer matches the recommended range for the product (for example ~1–2 mm for UPSIREN U6 PRO®). After reassembly, a faint imprint on the putty indicates good contact; if there is no imprint, add a little material; if material squeezes out excessively, reduce the amount. For less experienced users, K5 PRO® Mt. Olympos Edition is UV traceable under common inspection lamps, helping you confirm full contact.

Q: Do thermal putties flow or pump out over time?

A: CSGR putties are formulated to remain cohesive under clamp force. UPSIREN U6 PRO® is soft and lightly tacky to stay in place; UPSIREN UX PRO Ultra is higher viscosity to hold a 2–4 mm profile; K5 PRO® and K5 PRO® Mt. Olympos Edition have a gummy body that resists pump out under normal use. Correct layer thickness and even clamping are key to long term stability.

Q: Are these materials electrically conductive?

A: K5 PRO®, K5 PRO® Mt. Olympos Edition, UPSIREN U6 PRO®, and UPSIREN UX PRO Ultra are electrically non conductive. KRYO33 and K4 PRO pastes are also non conductive. Liquid Metal by CSGR is electrically conductive and must be applied carefully; avoid aluminum and insulate nearby SMDs. Many users frame the application with K5 PRO® to help contain liquid metal.

Q: What performance differences should I expect between pastes and putties?

A: Pastes form the thinnest bond line on flat surfaces and yield very low thermal resistance—KRYO33 excels here. Putties achieve contact over millimeter scale gaps and complex geometries. UPSIREN UX PRO Ultra, UPSIREN U6 PRO®, K5 PRO®, and K5 PRO® Mt. Olympos Edition are designed for VRAM/VRM clusters, thin heat spreaders, and compact cooling assemblies where paste alone fails.

Q: What is a phase change thermal pad and when should I use PTM7950 by CSGR®?

A: PTM7950 by CSGR® (40 × 40 × 0.25 mm) is solid at room temperature and softens near typical operating temperatures, flowing to fill micro gaps under pressure. It is ideal for many modern CPU and GPU dies where a consistent, clean up friendly interface is desired. It can be combined with K5 PRO® around the die on surrounding VRAM or power components.

Q: How long until PTM7950 by CSGR® reaches peak performance?

A: Expect full performance after a few thermal cycles—heating to operating temperature and cooling back down—over one to three days of normal use. Thermal cycling allows the material to flow microscopically, conforming to surface asperities and reducing interfacial resistance.

Q: How long do these materials last in service?

A: K4 PRO is engineered for long term “apply and forget” use in terminals, fanless systems, and embedded devices that will not be re opened for routine maintenance. KRYO33 has long service life and no curing time. Properly applied putties do not dry out in normal operation when installed at the recommended thickness and clamped evenly. As always, verify temperatures after service and periodically during sustained heavy use.

Q: Do I need to replace every pad with putty during maintenance?

A: Replace interfaces that show poor contact, heavy compression set, or dried out material. In mixed assemblies, use a paste or PTM7950 by CSGR® on the die and putty on VRAM/VRM. Do not use putty on flat, high pressure die surfaces designed for a thin paste or phase change interface.

Q: What do the asterisks next to thermal conductivity mean?

A: An asterisk next to a thermal conductivity value indicates it was obtained using Computer Systems’ internal comparative laboratory method.

Q: What devices are these products compatible with?

A: Examples include gaming laptops and desktop GPUs, consoles, routers and small form factor devices, LED panels, and industrial PCs.

Q: Where are your products manufactured?

A: CSGR materials are produced in Thessaloniki, Greece (European Union). Research, development, and quality control are conducted by Computer Systems in the EU. Several products—including UPSIREN U6 PRO®—were developed through scientific research projects funded in Greece and the EU.

Q: What makes CSGR products different from others in the same categories?

A: Consistent EU manufacturing and quality control; DIY friendly rheology tuned for realistic gap ranges; clear guidance on thickness and use cases; long field history since 2013 for K5 PRO®; specialized options for demanding scenarios such as K5 PRO® Mt. Olympos Edition for 1–4 mm gaps and next generation GDDR7/DDR7 VRAM thermals; and carefully matched combinations such as PTM7950 by CSGR® (for dies) plus a CSGR thermal putty (for surrounding components).

Q: How can I recognize original CSGR products and avoid counterfeits?

A: Buy from Computer Systems or authorized sellers. Check that the product name and UPC/EAN match your listing. Packaging print quality should be clean and consistent; for UPSIREN UX PRO Ultra and UPSIREN U6 PRO®, the packaging design is registered and copyright protected—unusual packaging or typography is a red flag. Avoid items with missing accessories or improvised labels. If in doubt, contact Computer Systems with photos for verification.

Q: What is special about K5 PRO® Mt. Olympos Edition compared to standard K5 PRO®?

A: It is tuned for larger gap ranges (1–4 mm) and high output, high density memory such as GDDR7/DDR7 VRAM on modern graphics boards; it includes a UV traceable additive for contact inspection; and it maintains cohesive contact under sustained thermal loads typical of powerful desktop GPUs and workstations.

Q: Which products are best for the newest high power GPUs and consoles?

A: For many 3000/4000/5000 series desktop GPU boards and modern consoles, two common combinations are: PTM7950 by CSGR® on the GPU die plus UPSIREN UX PRO Ultra or UPSIREN U6 PRO® on surrounding VRAM/VRM; or K5 PRO® Mt. Olympos Edition on VRAM/VRM where 1–4 mm gaps are present. Always phrase public compatibility as “compatible with …” to meet marketplace rules.

Q: Can a beginner apply these products?

A: Yes. Putties such as K5 PRO® and UPSIREN U6 PRO® are forgiving to place and adjust; UPSIREN UX PRO Ultra includes sleeves to hand mold the layer. Follow the suggested thickness ranges, reassemble evenly, and check for imprint/contact after tightening. PTM7950 by CSGR® requires careful alignment but is clean and repeatable once positioned.

Q: Is Liquid Metal by CSGR safe to use near other components?

A: Liquid metal is electrically conductive. Mask or frame the application and keep it away from aluminum. Many users apply a perimeter of K5 PRO® to help contain it. If you are uncertain, use a non conductive paste such as KRYO33 on the die instead.

Q: My heatsink is thin or flexible—what should I choose?

A: UPSIREN U6 PRO® is designed for thin form factor heatsinks used in many gaming laptops and slim consoles. It is soft, just sticky enough to stay in place, and applies easily even for amateur users; 1–2 mm is the typical working thickness.

Q: What should I do if the gap is very large or uneven?

A: UPSIREN UX PRO Ultra and K5 PRO® Mt. Olympos Edition are the preferred options for 2–4 mm interfaces. UX PRO Ultra has higher viscosity for shape retention; Olympos Edition offers UV visible inspection and broad device compatibility wording such as compatible with recent high end graphics boards using GDDR7/DDR7.

Q: Where can I use K4 PRO and how is it different from KRYO33?

A: K4 PRO is a low viscosity silicone based thermal paste designed for longevity—ideal in terminals, business systems, embedded and fanless devices intended to run for years without re opening. KRYO33 is a high performance, particle engineered paste for maximum heat transfer on clamped dies where performance is the priority.

Q: How should I clean and prepare surfaces?

A: Power down the device, disconnect power, and observe ESD precautions. Remove old paste or pads, then clean contact areas with high purity isopropyl alcohol and lint free swabs. Let surfaces dry completely before applying new material.

Q: Do your kits include everything I need?

A: Most listings specify exactly what is included; for example, many thermal putty packages include a wooden applicator and some include a precision tip. Check the “Packet includes” section of each listing to know exactly what you will receive.

Q: Where can I get help choosing between products?

A: Use our comparison tables on the site and the thickness guidance in this FAQ. If you still have questions, contact Computer Systems support with your device model, the measured gap, and photos of the interface.

Q: What if I need to undo a repair or adjust the application?

A: Non conductive putties like K5 PRO®, K5 PRO® Mt. Olympos Edition, UPSIREN U6 PRO®, and UPSIREN UX PRO Ultra remain workable; you can lift the heatsink, reshape or thin the layer, and reassemble. Clean tools and surfaces if contamination is visible.

Q: Any final safety notes?

A: Work on a static safe surface, avoid short circuits, and verify that the material you select matches the intended gap and device type. Re check temperatures after reassembly.

Reviews

There are no reviews yet.