Frequently Asked Questions

Comparison – Thermal Putties (K5‑PRO®, UPSIREN U6 PRO, UPSIREN UX PRO Ultra, K5 PRO Mt. Olympos Edition)

| Product | Type / Feel | Thermal conductivity* | Ideal layer / gap | Use cases & compatibility | Why choose it? | Best used for |

| K5‑PRO® | Gummy, form‑stable thermal putty | >5.3 W/m·K* | ≈0.5–3 mm; ideal at ≥1 mm | Compatible with Apple iMac, PlayStation 4, Nintendo Switch, various NVIDIA GeForce GTX‑10‑series boards, and many laptops and routers | Trusted since 2013; widely used by repair communities; easy for DIY users; pairs well with KRYO33 or PTM7950 by CSGR on the main die | Replacing soft pads on VRAM/VRM and mixed‑height clusters; general pad replacement in older and mainstream systems |

| UPSIREN U6 PRO | Soft, lightly tacky, easy‑spreading putty | 12.8 W/m·K* | ≈1–2 mm | Compatible with gaming laptops including Acer Nitro, ASUS ROG Zephyrus G14, MSI GS66 Stealth, Lenovo Legion, Dell G15 | Great heat conductivity without causing bending on thin and sensitive heat sinks. Beginner‑friendly. | Thin heat‑sink designs: gaming laptops and slim consoles; GDDR6 VRAM and controller chips |

| UPSIREN UX PRO Ultra | High‑viscosity, hand‑moldable putty | 16.8 W/m·K* | 2–4 mm | Compatible with PlayStation 5, Xbox Series X, NVIDIA GeForce RTX 3080/3090/4080/4090, AMD Radeon RX 6800/6900/7900 series | Resists pump‑out during long, hot workloads; shape with finger sleeves, then press for a clean footprint | Water‑cooling cold plates, desktop GPUs, and high‑power consoles where gaps are large and paste cannot maintain contact |

| K5 PRO Mt. Olympos Edition | UV‑reactive, cohesive putty (advanced K5‑PRO®) | >15 W/m·K* | 1–4 mm | Compatible with platforms using GDDR6/GDDR7; examples include NVIDIA GeForce RTX 4080/4090 and upcoming GDDR7 boards | UV‑visible coverage check; stable from −80 °C to 170 °C; includes application tools | Next‑gen high‑density VRAM (GDDR6/GDDR7), power stages, laptops/GPUs needing visual verification of spread |

Comparison – Pastes & Special Interfaces (KRYO33, K4‑PRO, PTM7950 by CSGR, Liquid Metal by CSGR)

| Product | Type | Thermal conductivity* | Bond‑line behavior | Best used for | Use cases & compatibility | Why choose it? |

| KRYO33 | High‑performance, non‑conductive thermal paste (solid particles only, ultra‑fine size) | >13 W/m·K* | Spreads thin; no curing time; fills micro‑gaps with ultra‑small particles for low resistance | CPU/GPU dies where the heatsink is flat and clamped firmly; overclocking and high load | Pairs perfectly with K5‑PRO® or UPSIREN putties on surrounding VRAM/VRM in laptops and desktops | Zero electrical conductivity; long service life; optimized particle size for maximum non‑conductive performance |

| K4‑PRO | Low‑viscosity silicone thermal paste | >4.6 W/m·K* | Maintains a thin, wetting film for years; designed for longevity | Business PCs, terminals, kiosks, fanless and industrial systems that will rarely be reopened | Complements K5‑PRO® on the same device (die = K4‑PRO; VRAM/VRM = K5‑PRO®); compatible with Apple iMac and PlayStation 2 | Apply‑and‑forget behavior; stable up to ~220 °C. Made to touch chips, not cheeks. |

| PTM7950 by CSGR (40×40×0.25 mm) | Phase‑change pad | 8.5 W/m·K* | Softens near ~45 °C and flows to fill micro‑gaps; returns to solid when cool | Modern CPU/GPU dies where consistent, clean assembly is required; common laptop and desktop applications | Combines well with K5‑PRO® on adjacent VRAM/VRM components | Typical 0.25 mm thickness suits most cooler tolerances; durable across thermal cycles |

| Liquid Metal by CSGR | Gallium‑based liquid metal (electrically conductive) | 79 W/m·K* | Forms an ultra‑thin metallic interface; requires careful, controlled application | Direct‑die CPU/GPU where maximum heat flux must be removed; compact water‑cooling blocks | Compatible with K5‑PRO® perimeter to help prevent migration; avoid aluminum; use on copper or nickel‑plated surfaces | Includes precision tips; intended for users who follow safety guidance |

CSGR thermal materials – Frequently Asked Questions

Q: What is the difference between thermal paste, thermal putty (sometimes called a “liquid thermal pad”), and a thermal pad?

A: Thermal paste is a thin compound used on flat, tightly clamped interfaces such as a CPU/GPU die to a heatsink. Thermal putty is a soft, formable material designed to bridge larger, uneven gaps where a normal paste cannot maintain contact—for example around VRAM or power stages. A thermal pad is a pre cut sheet used by manufacturers to fill gaps quickly during assembly. In many repairs, thermal putty can replace pads to restore contact with better conformity and easier fit when heights vary.

Q: When should I choose a thermal putty instead of a pad or paste?

A: Choose a putty when the interface has mixed heights or gaps above roughly 0.5 mm. K5 PRO® (~0.5–3 mm, ≈1 mm optimal), UPSIREN U6 PRO® (~1–2 mm), K5 PRO® Mt. Olympos Edition (1–4 mm), and UPSIREN UX PRO Ultra (2–4 mm) are purpose built for these conditions. For flat, high pressure die interfaces (CPU/GPU), a paste such as KRYO33 or K4 PRO is appropriate; a phase change pad such as PTM7950 by CSGR® works where the heatsink exerts uniform pressure and you want clean, repeatable assembly.

Q: How do I estimate the correct thickness when replacing a pad with putty?

A: Disassemble and clean the area, then dry fit the heatsink without fully tightening. Measure the original pad if available. Start with a thin film and build until the total layer matches the recommended range for the product (for example ~1–2 mm for UPSIREN U6 PRO®). After reassembly, a faint imprint on the putty indicates good contact; if there is no imprint, add a little material; if material squeezes out excessively, reduce the amount. For less experienced users, K5 PRO® Mt. Olympos Edition is UV traceable under common inspection lamps, helping you confirm full contact.

Q: Do thermal putties flow or pump out over time?

A: CSGR putties are formulated to remain cohesive under clamp force. UPSIREN U6 PRO® is soft and lightly tacky to stay in place; UPSIREN UX PRO Ultra is higher viscosity to hold a 2–4 mm profile; K5 PRO® and K5 PRO® Mt. Olympos Edition have a gummy body that resists pump out under normal use. Correct layer thickness and even clamping are key to long term stability.

Q: Are these materials electrically conductive?

A: K5 PRO®, K5 PRO® Mt. Olympos Edition, UPSIREN U6 PRO®, and UPSIREN UX PRO Ultra are electrically non conductive. KRYO33 and K4 PRO pastes are also non conductive. Liquid Metal by CSGR is electrically conductive and must be applied carefully; avoid aluminum and insulate nearby SMDs. Many users frame the application with K5 PRO® to help contain liquid metal.

Q: What performance differences should I expect between pastes and putties?

A: Pastes form the thinnest bond line on flat surfaces and yield very low thermal resistance—KRYO33 excels here. Putties achieve contact over millimeter scale gaps and complex geometries. UPSIREN UX PRO Ultra, UPSIREN U6 PRO®, K5 PRO®, and K5 PRO® Mt. Olympos Edition are designed for VRAM/VRM clusters, thin heat spreaders, and compact cooling assemblies where paste alone fails.

Q: What is a phase change thermal pad and when should I use PTM7950 by CSGR®?

A: PTM7950 by CSGR® (40 × 40 × 0.25 mm) is solid at room temperature and softens near typical operating temperatures, flowing to fill micro gaps under pressure. It is ideal for many modern CPU and GPU dies where a consistent, clean up friendly interface is desired. It can be combined with K5 PRO® around the die on surrounding VRAM or power components.

Q: How long until PTM7950 by CSGR® reaches peak performance?

A: Expect full performance after a few thermal cycles—heating to operating temperature and cooling back down—over one to three days of normal use. Thermal cycling allows the material to flow microscopically, conforming to surface asperities and reducing interfacial resistance.

Q: How long do these materials last in service?

A: K4 PRO is engineered for long term “apply and forget” use in terminals, fanless systems, and embedded devices that will not be re opened for routine maintenance. KRYO33 has long service life and no curing time. Properly applied putties do not dry out in normal operation when installed at the recommended thickness and clamped evenly. As always, verify temperatures after service and periodically during sustained heavy use.

Q: Do I need to replace every pad with putty during maintenance?

A: Replace interfaces that show poor contact, heavy compression set, or dried out material. In mixed assemblies, use a paste or PTM7950 by CSGR® on the die and putty on VRAM/VRM. Do not use putty on flat, high pressure die surfaces designed for a thin paste or phase change interface.

Q: What do the asterisks next to thermal conductivity mean?

A: An asterisk next to a thermal conductivity value indicates it was obtained using Computer Systems’ internal comparative laboratory method.

Q: What devices are these products compatible with?

A: Examples include gaming laptops and desktop GPUs, consoles, routers and small form factor devices, LED panels, and industrial PCs.

Q: Where are your products manufactured?

A: CSGR materials are produced in Thessaloniki, Greece (European Union). Research, development, and quality control are conducted by Computer Systems in the EU. Several products—including UPSIREN U6 PRO®—were developed through scientific research projects funded in Greece and the EU.

Q: What makes CSGR products different from others in the same categories?

A: Consistent EU manufacturing and quality control; DIY friendly rheology tuned for realistic gap ranges; clear guidance on thickness and use cases; long field history since 2013 for K5 PRO®; specialized options for demanding scenarios such as K5 PRO® Mt. Olympos Edition for 1–4 mm gaps and next generation GDDR7/DDR7 VRAM thermals; and carefully matched combinations such as PTM7950 by CSGR® (for dies) plus a CSGR thermal putty (for surrounding components).

Q: How can I recognize original CSGR products and avoid counterfeits?

A: Buy from Computer Systems or authorized sellers. Check that the product name and UPC/EAN match your listing. Packaging print quality should be clean and consistent; for UPSIREN UX PRO Ultra and UPSIREN U6 PRO®, the packaging design is registered and copyright protected—unusual packaging or typography is a red flag. Avoid items with missing accessories or improvised labels. If in doubt, contact Computer Systems with photos for verification.

Q: What is special about K5 PRO® Mt. Olympos Edition compared to standard K5 PRO®?

A: It is tuned for larger gap ranges (1–4 mm) and high output, high density memory such as GDDR7/DDR7 VRAM on modern graphics boards; it includes a UV traceable additive for contact inspection; and it maintains cohesive contact under sustained thermal loads typical of powerful desktop GPUs and workstations.

Q: Which products are best for the newest high power GPUs and consoles?

A: For many 3000/4000/5000 series desktop GPU boards and modern consoles, two common combinations are: PTM7950 by CSGR® on the GPU die plus UPSIREN UX PRO Ultra or UPSIREN U6 PRO® on surrounding VRAM/VRM; or K5 PRO® Mt. Olympos Edition on VRAM/VRM where 1–4 mm gaps are present. Always phrase public compatibility as “compatible with …” to meet marketplace rules.

Q: Can a beginner apply these products?

A: Yes. Putties such as K5 PRO® and UPSIREN U6 PRO® are forgiving to place and adjust; UPSIREN UX PRO Ultra includes sleeves to hand mold the layer. Follow the suggested thickness ranges, reassemble evenly, and check for imprint/contact after tightening. PTM7950 by CSGR® requires careful alignment but is clean and repeatable once positioned.

Q: Is Liquid Metal by CSGR safe to use near other components?

A: Liquid metal is electrically conductive. Mask or frame the application and keep it away from aluminum. Many users apply a perimeter of K5 PRO® to help contain it. If you are uncertain, use a non conductive paste such as KRYO33 on the die instead.

Q: My heatsink is thin or flexible—what should I choose?

A: UPSIREN U6 PRO® is designed for thin form factor heatsinks used in many gaming laptops and slim consoles. It is soft, just sticky enough to stay in place, and applies easily even for amateur users; 1–2 mm is the typical working thickness.

Q: What should I do if the gap is very large or uneven?

A: UPSIREN UX PRO Ultra and K5 PRO® Mt. Olympos Edition are the preferred options for 2–4 mm interfaces. UX PRO Ultra has higher viscosity for shape retention; Olympos Edition offers UV visible inspection and broad device compatibility wording such as compatible with recent high end graphics boards using GDDR7/DDR7.

Q: Where can I use K4 PRO and how is it different from KRYO33?

A: K4 PRO is a low viscosity silicone based thermal paste designed for longevity—ideal in terminals, business systems, embedded and fanless devices intended to run for years without re opening. KRYO33 is a high performance, particle engineered paste for maximum heat transfer on clamped dies where performance is the priority.

Q: How should I clean and prepare surfaces?

A: Power down the device, disconnect power, and observe ESD precautions. Remove old paste or pads, then clean contact areas with high purity isopropyl alcohol and lint free swabs. Let surfaces dry completely before applying new material.

Q: Do your kits include everything I need?

A: Most listings specify exactly what is included; for example, many thermal putty packages include a wooden applicator and some include a precision tip. Check the “Packet includes” section of each listing to know exactly what you will receive.

Q: Where can I get help choosing between products?

A: Use our comparison tables on the site and the thickness guidance in this FAQ. If you still have questions, contact Computer Systems support with your device model, the measured gap, and photos of the interface.

Q: What if I need to undo a repair or adjust the application?

A: Non conductive putties like K5 PRO®, K5 PRO® Mt. Olympos Edition, UPSIREN U6 PRO®, and UPSIREN UX PRO Ultra remain workable; you can lift the heatsink, reshape or thin the layer, and reassemble. Clean tools and surfaces if contamination is visible.

Q: Any final safety notes?

A: Work on a static safe surface, avoid short circuits, and verify that the material you select matches the intended gap and device type. Re check temperatures after reassembly.

CS-FLUX – Frequently Asked Questions

Q: What is CS FLUX and what makes it different from other fluxes?

A: CS FLUX is a halogen free, lead free, no clean soft gel flux formulated for electronics repair and microsoldering. At room temperature it behaves like a controllable gel; under heat it becomes very fluid and turns transparent so you can see pads and solder flow clearly. Unlike thick pastes that need pumps or heavy pressure, CS FLUX dispenses with light finger pressure directly from the applicator tube.

Q: Do I need a pump or pneumatic dispenser?

A: No. The soft gel body is tuned for low pressure, hand controlled dosing. Squeeze gently and it will place a precise micro drop where you need it—ideal for microscopes and tight clearances.

Q: How fine is the dosing—can I place a single tiny drop?

A: Yes. The included precision needle tip allows very small, repeatable drops. Because the gel is soft, it starts and stops cleanly without “stringing,” so you can wick just enough under a connector pad or QFN edge.

Q: What does “no clean” mean here? Do I ever need to clean it?

A: No clean means the residues are non corrosive and safe to leave in typical electronics repairs. If you need a cosmetically clean board, plan to apply conformal coating, or you simply prefer a spotless finish, wipe with high purity isopropyl alcohol after the joint cools.

Q: Will CS FLUX corrode copper, solder mask, or components over time?

A: No. It’s halogen free and formulated to avoid corrosive residues. It is designed for modern PCB finishes and components when used as directed.

Q: Is it suitable for beginners?

A: Yes. The transparency when hot, low effort dosing, and soft pre heat tack make it very forgiving. Many first time users report cleaner joints with fewer bridges on USB C/HDMI connectors, headers, and fine pitch ICs.

Q: Can I use it for BGA work as well as everyday SMD?

A: Yes. It supports BGA rework and reballing (wicking under the package during heat), but its biggest day to day advantage is on connectors, QFN/DFN, jumpers, and small modules.

Q: Does it smoke a lot?

A: CS FLUX is low fume compared to many rosin heavy formulas. You’ll still see some vapor as with any flux—work in a ventilated area or use a fume extractor for comfort.

Q: Is it electrically conductive?

A: No. CS FLUX is non conductive. Like any flux, avoid leaving excessive residue where insulation resistance is critical, and clean if your application requires it.

Q: Leaded or lead free solder—does it matter?

A: It works with both. The activation profile is designed for common repair alloys (SnPb and SAC).

Q: Can I use it with a soldering iron, hot air station, or IR plate?

A: Yes. It is compatible with iron only touch ups, hot air rework, and IR preheating/reflow setups.

Q: How much should I apply?

A: Less than you think. Start with a micro drop; as heat is applied the flux turns very fluid and spreads, activating the entire pad. Add more only if you see dull, stubborn wetting.

Q: Will parts slide around when I heat them?

A: The gel has a light tack at room temperature to help “stage” parts. As it liquefies, part drift is minimized by using just enough flux and maintaining even heat.

Q: Tips for USB C/HDMI/DC jack replacements?

A: Place a small line along the pad row, align, and heat evenly. The flux will wick under the footprint and turn clear so you can watch bridges form and collapse. After soldering, inspect and clean only if you want an appearance grade finish.

Q: Can it help with oxidized pads?

A: Yes. A small amount brushed across dull pads improves wetting before you tin or drag solder.

Q: How do I remove residues if I choose to clean?

A: After the board cools, wipe with high purity isopropyl alcohol and a lint free swab. For heavy areas, a brief soak and gentle brushing works well.

Q: Storage and longevity—what’s recommended?

A: Keep the cap on, store sealed in a cool, dry place, away from heat and sunlight. If it has been stored cold, let it return to room temperature before use for consistent viscosity.

Q: The gel seems thicker after storage—what should I do?

A: Allow it to warm to room temperature and knead the tube lightly before attaching the tip. Replace or rinse the tip if it has dried residues.

Q: Will it stain plastics or the solder mask?

A: Residues are usually thin and clear. Avoid prolonged soaking of porous plastics or elastomers; wipe any excess soon after work for best cosmetics.

Q: Can I use CS FLUX on large ground planes or heavy copper boards?

A: Yes, but preheating the board (hot plate or gentle hot air preheat) reduces thermal shock and improves flow on high mass areas.

Q: Is it safe around sensitive sensors or cameras on phones/tablets?

A: Use sparingly and shield optics from vapors while heating. The transparent behavior helps you keep flux away from lenses and membranes.

Q: Does it help with drag soldering pin headers and fine pitch ICs?

A: Absolutely. Place a micro bead along the pins and use a clean, tinned iron tip; the flux promotes even wetting so excess solder follows the tip instead of bridging.

Q: Can I reuse the precision tip?

A: Yes. Cap the tube between sessions. If the tip clogs, rinse with isopropyl alcohol, let dry, and reinstall. Keep a spare clean tip for microscope work.

Q: What quantities are available and what comes in the pack?

A: CS FLUX is available in single 5 g and 10 g tubes, dual 5 g (2×5 g), and triple 5 g (3×5 g) packs. Each tube includes a precision application tip. All packs are ready to use—no pump or extra hardware required.

CSGR Data Recovery Tools – Frequently Asked Questions

Q: Who are these tools for?

A: They’re designed so a careful DIY user can diagnose and fix many firmware related HDD problems at home or in a small workshop, without soldering or component replacement. Every kit includes step by step instructions. If you prefer, our team can guide you via optional remote access.

Q: What kinds of problems can they help with?

A: Firmware level issues on compatible HDDs—such as drives stuck busy (BSY), detected with wrong size (for example 0 MB/3 GB), or not recognized due to corrupt firmware modules or translator problems. They are not for mechanical damage (heads, motor, scratched platters).

Q: Will they work with my drive brand?

A: FW FXR and DFS are compatible with many Seagate SATA families (and certain Maxtor models that are Seagate equivalent). FileChecker by CS works with files on Windows systems regardless of drive brand because it analyzes data consistency after an image or recovery. When you list specific brands or models publicly, phrase it as “compatible with …”.

Q: I’m not an expert. Can I still use these?

A: Yes. The tools, manuals, and on screen prompts are written for users with limited experience. The hardware uses a simple serial connection—no soldering—to communicate with supported drives. If you get stuck, choose the remote assistance option and a specialist can walk you through the steps or perform the operation while you watch.

Q: What operating systems are supported?

A: The software is compatible with Windows 7, 8, and 10 on standard PCs. Admin rights are recommended during installation and use.

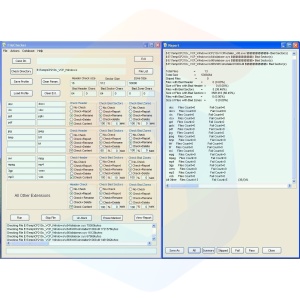

Q: What is the difference between FW FXR and DFS?

A: FW FXR focuses on automatic fixes for common Seagate firmware faults on supported families (for example BSY state, 0 MB size, bad translator). It’s built to be as push button as possible for DIY users. DFS (Diagnostics for Seagate) is a deeper diagnostic and repair environment that lets you analyze modules, run targeted tests, regenerate a translator, and perform model specific procedures using clear buttons and guided workflows.

Q: What exactly is inside the CS Data Recovery Tool Set?

A: The set bundles FW FXR hardware and software, DFS software, FileChecker by CS, connection accessories (USB to TTL/serial interface and pre made cables), a connector mask and torx driver where needed, plus detailed manuals. Buying the set saves cost and ensures you have everything required for supported Seagate SATA firmware cases from first diagnosis to final file integrity checks.

Q: What does FileChecker by CS do and when should I use it?

A: After you fix a firmware problem and image or mount the drive, FileChecker by CS scans folders and files to flag corruption, missing sectors, or mismatched metadata. It helps you verify which data is safe to copy and which needs re imaging. It’s brand agnostic—use it on any recovered Windows readable volume or image file.

Q: Can these tools recover the majority of Seagate firmware cases?

A: In typical, firmware only scenarios (no head or media damage), users report that the toolset can help recover a large portion of cases—often around 80% for compatible Seagate families—when procedures are followed carefully. Results depend on the drive’s condition and previous attempts; no tool can guarantee recovery.

Q: Are there limitations on newer Seagate drives?

A: Yes. Some newer Seagate SATA models use locked firmware architectures that limit third party access; certain functions may be restricted or unavailable. In such cases, remote assistance can help you identify options before you proceed.

Q: Do I need to open the drive?

A: No. All procedures are performed through the drive’s external interfaces and service port. Opening a drive requires a clean environment and is not part of these DIY tools.

Q: Is soldering required?

A: No soldering is required. You connect via a provided serial/TTL lead and standard SATA power/data.

Q: Will these tools help with head crashes or clicking drives?

A: No. Persistent clicking, grinding, or failure to spin points to mechanical damage. Do not run firmware repairs on a physically damaged drive. If critical data is at risk, stop and contact a professional lab.

Q: What about privacy if I request remote help?

A: Remote assistance is optional and performed with your permission through a secure remote desktop session. You remain in control, can watch every step, and can terminate the session at any time.

Q: Do you have tutorial videos?

A: Yes. We publish walkthroughs and case tips on our YouTube channel: computersystemsgr.

Q: What if the drive goes to BSY again or shows 0 MB after a fix?

A: That usually means the translator needs regeneration or additional model specific steps. Re run the guided function in FW FXR or use the targeted commands in DFS. If you’re unsure, request remote assistance so a specialist can review the session log and advise next actions.

Q: Will using the tools harm my data?

A: The procedures target firmware and are designed to be safe for supported cases. That said, any HDD already has an underlying fault. Follow the manual, avoid power interruptions, and, once the drive is recognized, image it immediately before doing anything else.

Q: Can I test a drive that has started to fail but still reads?

A: Yes—use DFS to run non destructive diagnostics first. If read instability is detected, prioritize imaging with your preferred imager and then run FileChecker by CS to assess file integrity.

Q: How long does a typical fix take?

A: Simple BSY or wrong size cases often complete in one short session. More complex translator tasks can take longer—especially if the drive reads marginally. Always plan enough time for imaging after the repair.

Q: What tools do I need in addition to the kit?

A: A Windows PC, SATA power and data leads, and a stable power source. The kit includes the serial interface, cables, masks, driver bit, and software manuals.

Q: Can I return or re use the hardware on multiple drives?

A: The hardware interface is re usable. Software usage terms are specified in the license; many buyers use the tools repeatedly for their own drives or as part of a repair business.

Q: When should I choose the full set instead of a single product?

A: Choose the set if you want a start to finish workflow: FW FXR for common quick fixes, DFS for deeper diagnostics on compatible families, and FileChecker by CS to validate your results. It minimizes downtime and gives you options if the first approach isn’t enough.

Q: What if I’m unsure which tool to start with?

A: Begin with the set’s quick checklist. As a rule of thumb: wrong size or BSY on a compatible Seagate model → FW FXR; not recognized or inconsistent IDs on a compatible family → DFS diagnostics; after recognition and imaging → FileChecker by CS to validate files. If uncertain, ask for remote assistance.

Q: Do you offer help if I don’t want to risk a valuable drive?

A: Yes. You can ship the drive for service or book a remote session where a specialist performs the firmware steps while you observe. Many customers start DIY and switch to remote help at the tricky part.

Q: After I recover the drive, is it safe to keep using it?

A: No. Once you’ve imaged and copied critical data, retire the drive. Firmware faults can return, and marginal drives often degrade. Use the recovered data on a healthy replacement drive.